About Case

Cars are updated every year, and parts are constantly updated. However, for some vehicles that have been running for more than 20 years, it is often difficult to find parts during maintenance, resulting in unsatisfactory service for users. After seeing our advertisement, customers provided us with a 2013 Audi A8 4.0T gearbox with the attitude of trying it out

Customer demand

- User region: United States

- User budget: 10000

- Contact date: 2022-03-08

- Date of cooperation: 2022-03-20

Problems encountered

There is a shrugging phenomenon when the transmission is running at low speed

Abnormal sound, jitter fault

- 1: Conduct road test, the engine tachometer is very stable without fluctuation when the phenomenon of towering car appears,

- 2: The whole body, including the accelerator pedal under the foot, vibrates

The vehicle is also running at low and medium speed to be able to hear the "whiner" sound that should be transmitted inside the transmission

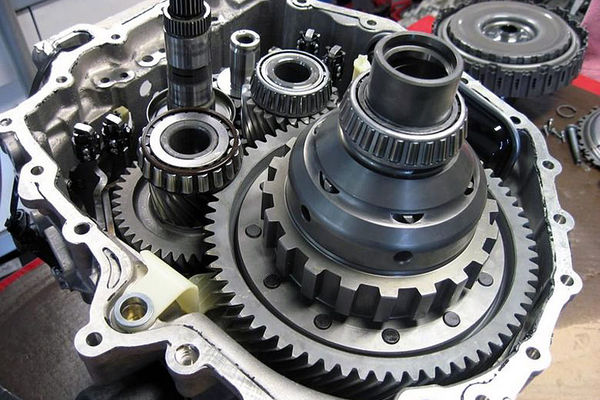

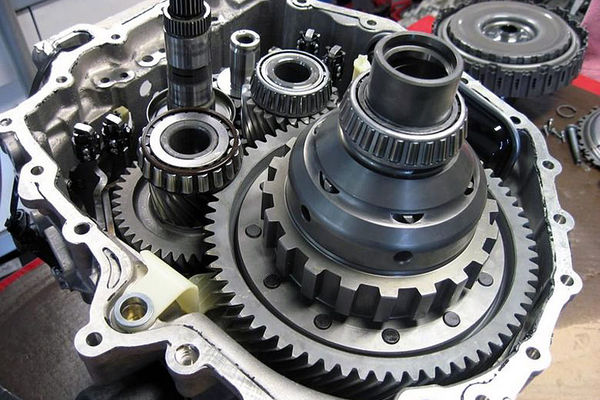

After decomposing the transmission, you can see the sprocket and chain have obvious wear

- 1:after chain drive wear

- 2: During the driving process, the chain rolling friction in the sprocket, due to the rough surface of the sprocket wear brought about by the sensationalism

How to solve

Replace all worn parts

Replace all worn parts with our spare parts

- 1. Drive sprocket shaft assembly, driven sprocket cylinder and fixed plate (can be separated from the differential drive shaft), chain and other components

- 2: Clean the hydraulic valve body (spool valve box) and readjust the working gap of the forward gear clutch

Test run after newly assembled transmission

When the transmission temperature to match the adaptive temperature requirements after the successful adaption of the vehicle operation is normal, and the dynamic data is also very normal.

- 1: Driving matching under partial load for the tenth group (forward gear matching data) and eleventh group (reverse gear matching data)

- 2: the air filter, reverse stop oil is recommended to change once every 3 months, and refueling to 1/2 of the oil level observation under the shutdown state

Customer voice

Through our custom-made reverse stop designed for customers, it is more non-permeable in the process of use, reducing maintenance costs and improving work efficiency